A Strategic Guide for Data-Driven Process Improvement

A comprehensive guide to leveraging data for effective process improvement and business transformation.

What You'll Learn

This guide walks you through five practical steps to turn process mining insights into actual improvements. You’ll learn how to get stakeholder buy-in, prioritize opportunities, plan implementation, execute changes, and sustain improvements over time.

Congratulations! You’ve analyzed your process with process mining and identified some real improvement opportunities. You have data, evidence, and a compelling case for change.

But here’s the uncomfortable truth: insights alone don’t improve processes.

It’s surprisingly easy to get stuck in the analysis phase. Analysis is intellectually satisfying. Finding another interesting pattern, running another comparison, building another dashboard: these feel like progress. But without action, they’re just expensive exploration.

The real value of process mining comes when insights become improvements. When cycle times actually shrink. When bottlenecks actually clear. When customer satisfaction actually increases.

This guide helps you bridge the gap between knowing what to do and actually doing it.

This blog is part of our process improvement series. See also our guides on analyzing your process and monitoring improvements for the complete improvement cycle.

Process improvements rarely happen in isolation. The analyst who discovered the insight is often not the person who can implement the change.

Your improvement initiative needs engagement from:

| Role | Contribution |

|---|---|

| Process owners | Authority to approve changes, accountability for outcomes |

| Frontline employees | Real-world knowledge, adoption of new practices |

| Managers | Resource allocation, team motivation, escalation |

| IT staff | System changes, data access, technical feasibility |

| Finance | Business case validation, budget approval |

| Compliance | Regulatory requirements, risk assessment |

Not every improvement needs every stakeholder. Match involvement to the scope and nature of the change.

Don’t wait until you have a complete plan to involve stakeholders. Early engagement:

People support what they help create.

Someone must be responsible for driving implementation forward. This could be:

Without clear accountability, improvements drift. Tasks get deprioritized. Momentum fades. Make sure everyone knows who’s driving.

Common Pitfall

Analysts often want to keep analyzing rather than implementing. If you’re the analyst, recognize this tendency and push yourself (or your organization) toward action. The next analysis round will be more valuable with real improvement data to study.

You probably have more improvement ideas than you can pursue at once. Prioritization prevents spreading too thin and ensures you focus on what matters most.

Assess each opportunity against multiple factors:

Impact

Feasibility

Risk

Alignment

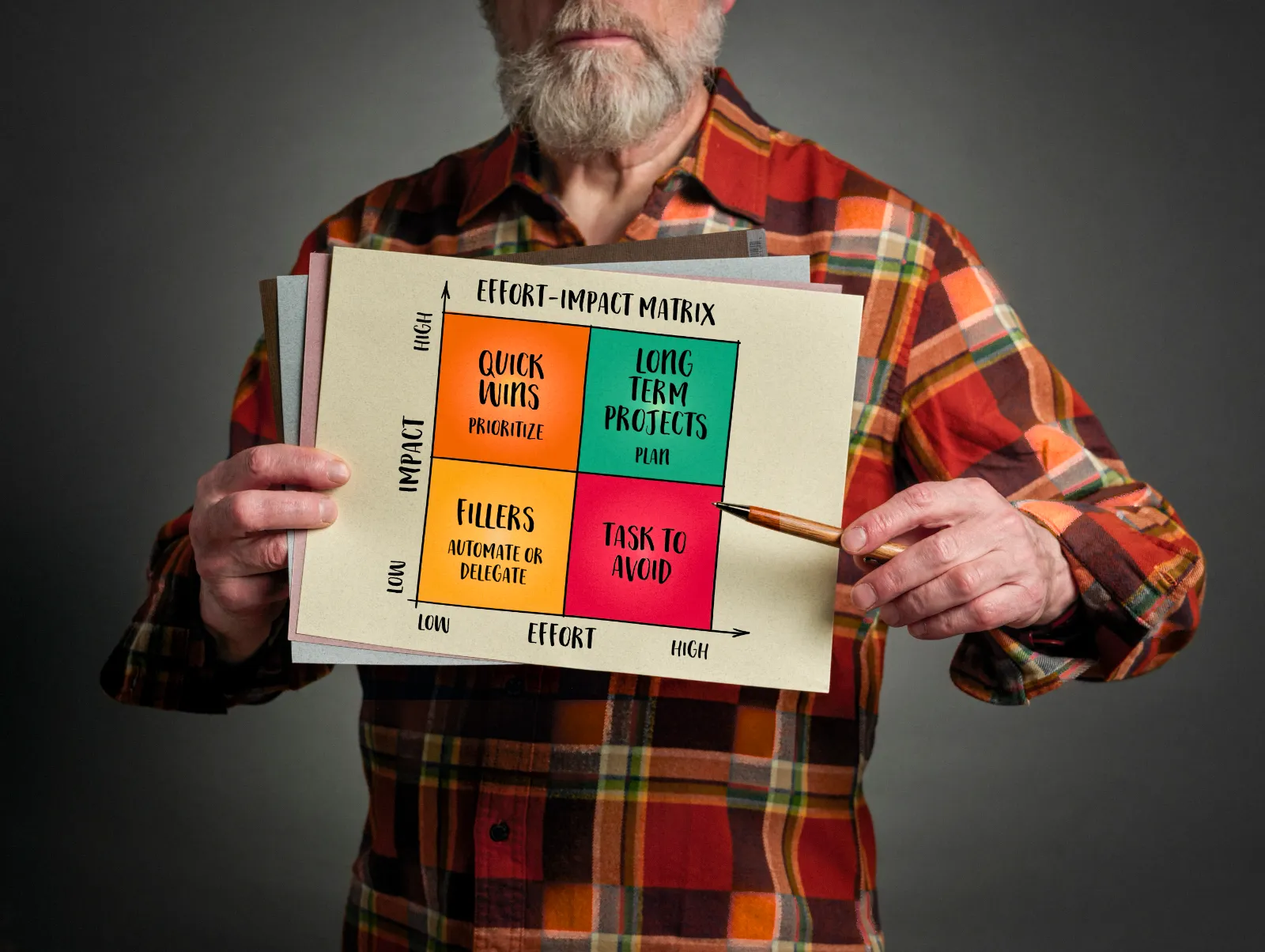

A simple 2x2 matrix helps visualize priorities:

| Easy to Implement | Hard to Implement | |

|---|---|---|

| High Impact | 🎯 Quick Wins - Do first | ⭐ Strategic - Plan carefully |

| Low Impact | 🔧 Fill-ins - Do if capacity | ❌ Avoid - Not worth effort |

A healthy improvement portfolio includes:

Don’t pursue only quick wins, or you’ll never make significant progress. But don’t pursue only big changes either, or you’ll lose momentum waiting for results.

Record why you’re prioritizing certain improvements:

This clarity helps when priorities are questioned and ensures consistent decision-making across the team.

With priorities set, create detailed plans for your selected improvements.

For each improvement, specify:

Example:

“Reduce average approval wait time from 48 hours to 24 hours within 3 months of implementation.”

Break the improvement into concrete tasks:

Don’t over-plan, but have enough structure that progress is trackable and accountable.

Every change has risks. Think through:

Having a Plan B doesn’t mean you expect Plan A to fail. It means you’re prepared.

Process improvements often require people to work differently. Consider:

Technical changes are often easier than behavioral changes. Budget time and attention accordingly.

Before execution, ensure key stakeholders are aligned:

A plan that no one supports is just a document.

Now comes the actual work of making changes happen.

When possible, test changes on a limited scope before full rollout:

Pilots reduce risk and generate proof points that help convince skeptics.

Keep stakeholders informed as implementation progresses:

People are more supportive when they feel informed and included.

Don’t wait until the end to see if it’s working. Use ProcessMind dashboards to track metrics during implementation:

Early detection of issues enables course correction before problems compound.

Implementation rarely goes exactly as planned. When obstacles arise:

Flexibility isn’t failure. It’s smart implementation.

Pro Tip

Document what you learn during implementation. Future improvement projects benefit from knowing what worked, what didn’t, and what you’d do differently.

Implementation is just the beginning. To deliver lasting value, improvements need to stick.

Use the same process mining approach that identified the opportunity to verify the improvement:

If results fall short of expectations:

Move from implementation tracking to sustained monitoring:

Improvements can fade over time as old habits resurface or conditions change. Monitoring catches regression early.

Give process owners and stakeholders direct access to monitoring dashboards:

Transparency reinforces accountability and maintains focus.

When improvements deliver results:

Recognition motivates continued improvement efforts and builds organizational commitment to process excellence.

Successful implementation often reveals new opportunities:

Feed these into your next analysis cycle. Continuous improvement is continuous.

The three phases (analyze, implement, monitor) form a continuous cycle:

Each cycle builds on the previous. Each round of improvement creates data for the next analysis. Organizations that master this cycle continuously get better.

Symptoms: People don’t adopt new practices, revert to old ways, complain about changes.

Solutions:

Symptoms: Improvement work keeps getting deprioritized for urgent operational needs.

Solutions:

Symptoms: The improvement keeps expanding, adding more features, taking longer.

Solutions:

Symptoms: You can’t tell if the improvement actually worked.

Solutions:

ProcessMind supports your entire improvement journey:

From first insight to sustained improvement, ProcessMind gives you the visibility to know what’s working and what needs attention.

Ready to turn your process insights into real results? Start your free trial and begin your improvement journey today.

Related Resources:

A comprehensive guide to leveraging data for effective process improvement and business transformation.

Compare Celonis process mining with ProcessMind for 2025. Discover which process mining software fits your business needs, budget, and goals.

Compare Disco and ProcessMind to find the best fit for your team's process mining needs in 2025. Discover key features, pricing, and use cases.

See how ProcessMind compares to SAP Signavio for process mining, modeling, and simulation. Find the best fit for your business in 2025.

Instant access, no credit card, no waiting. Experience how mapping, mining, and simulation work together for smarter, faster decisions.

Explore every feature, uncover deep insights, and streamline your operations from day one.

Start your free trial now and unlock the full power of Process Intelligence, see real improvements in under 30 days!