A Strategic Guide for Data-Driven Process Improvement

A comprehensive guide to leveraging data for effective process improvement and business transformation.

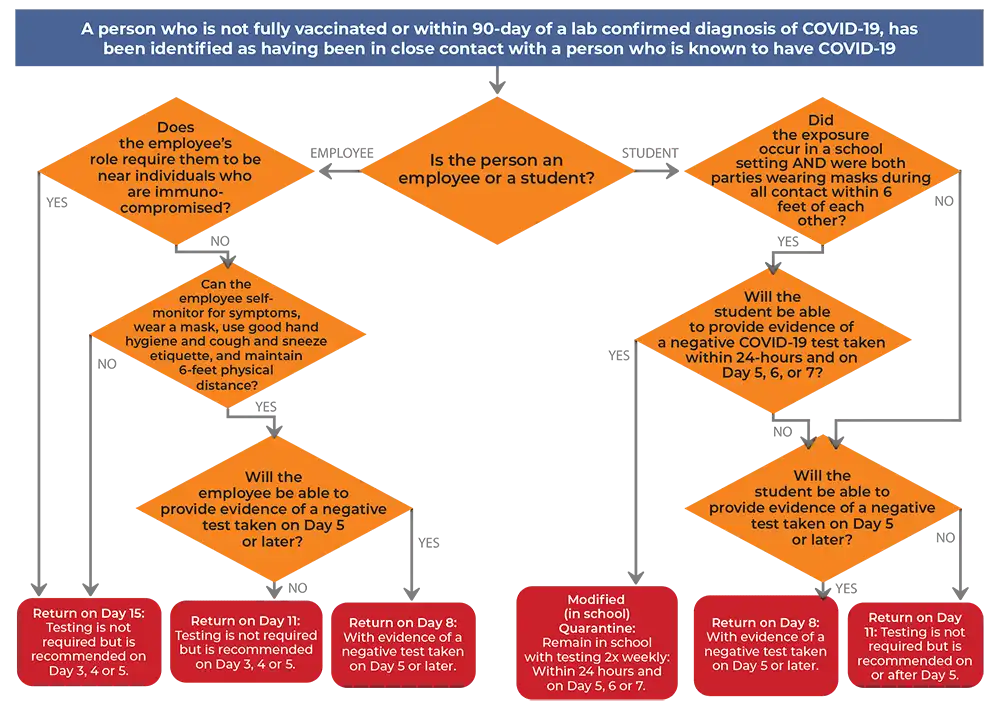

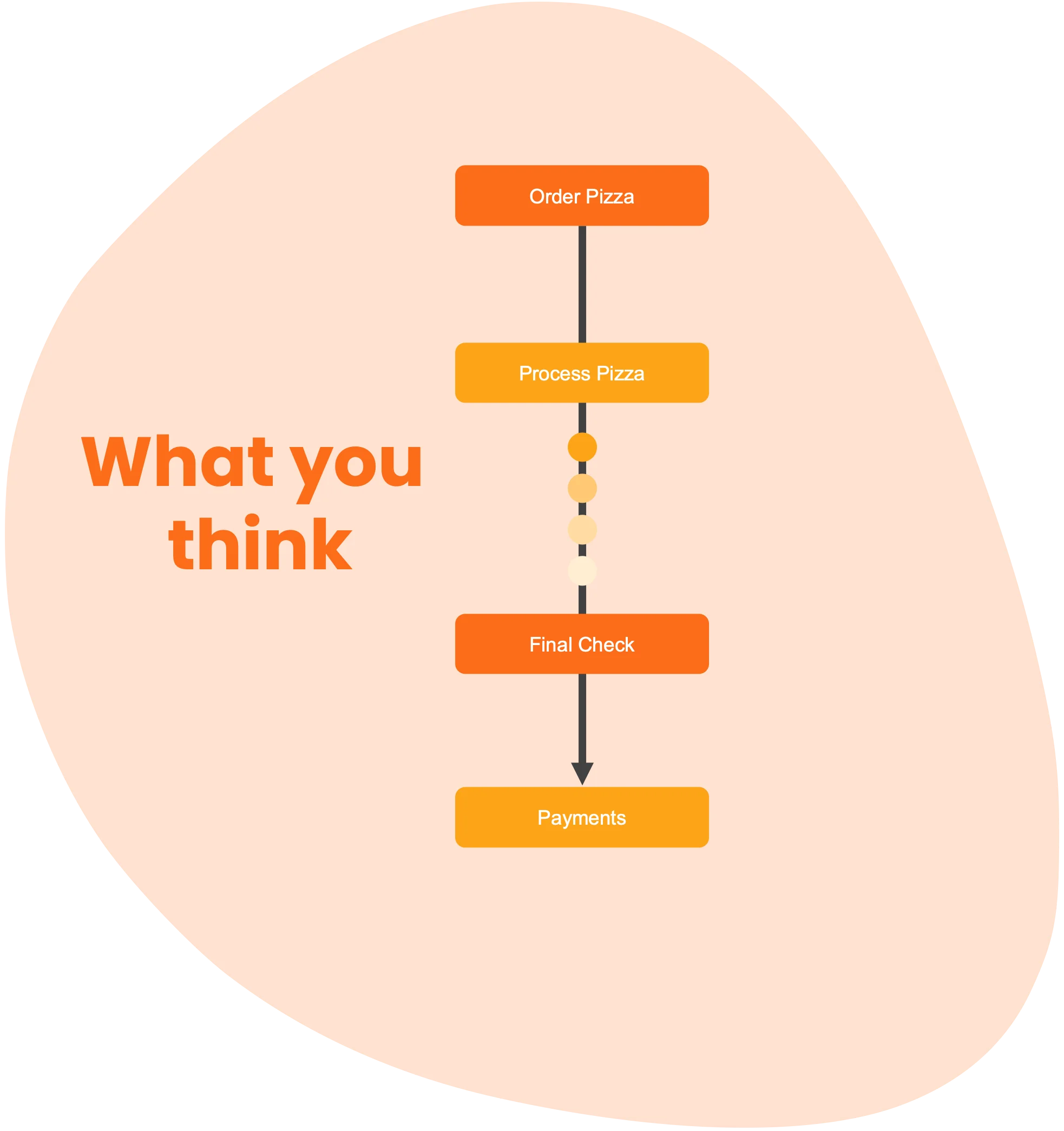

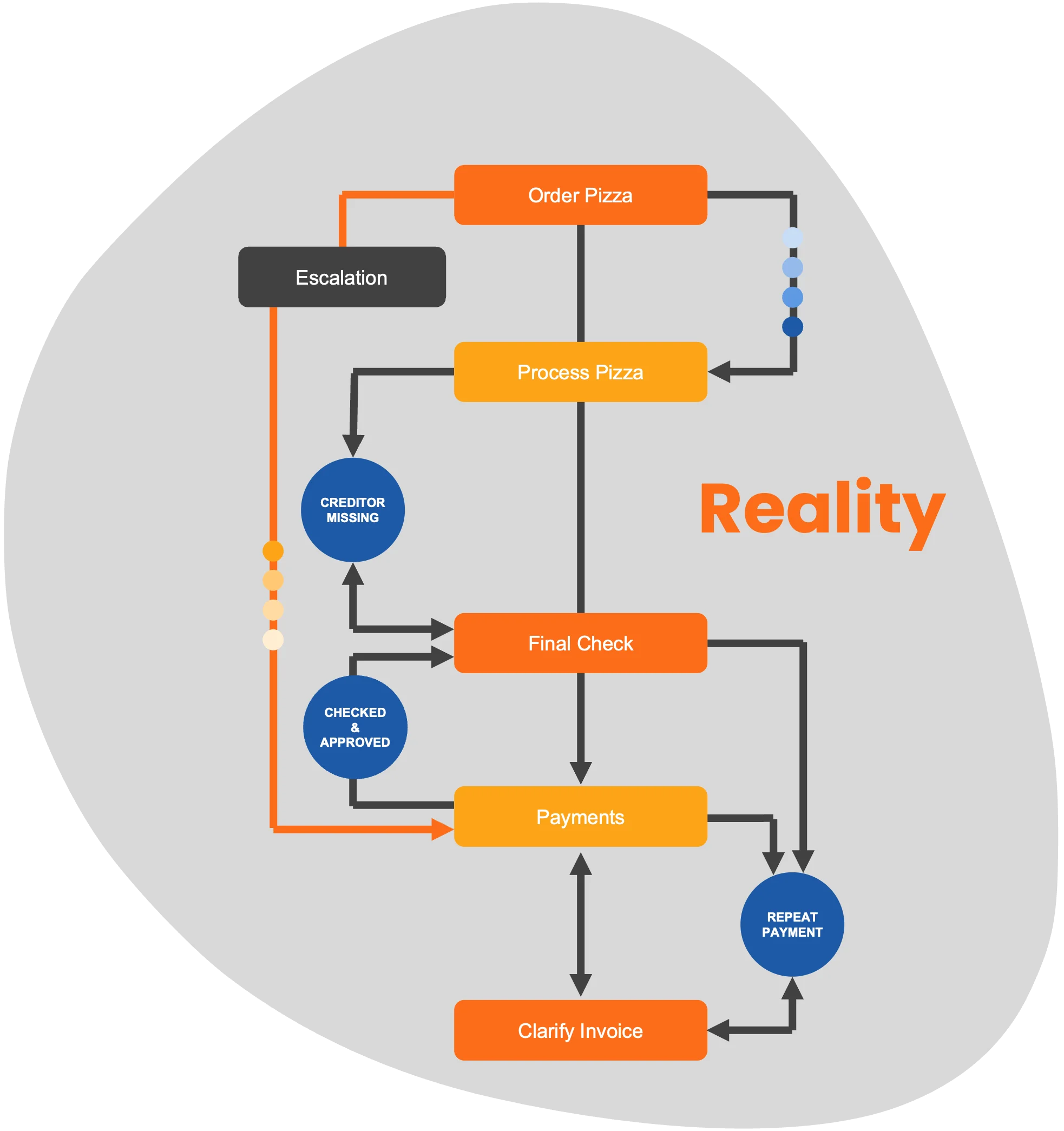

Process Modeling is a visual tool that illustrates how work gets done, showing a series of events that lead to an end result. Also known as a flowchart or workflow diagram, it helps businesses spot areas for improvement. This guide covers process maps, their types, and benefits, and offers best practices for using Process Modeling in your business. Finally, we compare Process Modeling and Process Mining, and how they can be combined for a comprehensive approach to process analysis and improvement.

Here are 20 reasons why you need Process Modeling in your business:

Introduced by Frank Gilbreth in 1921 to members of ASME as the presentation “Process Charts—First Steps in Finding the One Best Way”, Process Modeling has evolved into Business Process Modeling (BPM), which became popular in the 1990s.

Process Modeling

Process Modeling is a visual tool that illustrates how work gets done by showing a series of events that produce an end result. It is often used to identify areas for improvement within a business or organization. Process maps help standardize repetitive tasks, visualize workflows, and boost productivity by spotting bottlenecks and inefficiencies. They enable teams to coordinate inputs and decision points, and communicate the steps and dependencies in a process from start to finish.

Process Modeling

Process Modeling is an advanced and detailed approach that captures and represents enterprise processes for analysis, improvement, and automation. Business Process Modeling (BPM) often involves the use of IT systems like event logs to accurately model processes. BPM is typically performed by business analysts in collaboration with subject matter experts. It is primarily used in business process management, software development, and systems engineering. BPM allows for a deeper analysis of processes, enabling organizations to simulate different scenarios, predict outcomes, and make data-driven decisions. It provides a comprehensive understanding of business processes and supports continuous improvement by identifying inefficiencies and developing alternatives.

Process Modeling and process modeling are both essential for understanding and optimizing workflows, but they serve different purposes. The table below highlights their distinctions in terms of purpose, detail level, tools, collaboration, and use cases.

| Aspect | Process Modeling | Process Modeling |

|---|---|---|

| Purpose | Focuses on visualizing and understanding the current state of a process to identify areas for improvement. | Aims to analyze, improve, and automate processes, often using advanced tools and techniques. |

| Detail Level | Provides a high-level overview of a process, showing the sequence of steps and interactions. | Offers a detailed and comprehensive representation of a process, including data flows, decision points, and potential outcomes. |

| Tools and Techniques | Utilizes simple visual tools like flowcharts and diagrams. | Employs advanced modeling techniques and software tools, such as BPMN (Business Process Model and Notation). |

| Collaboration | Often involves team members and stakeholders to create a shared understanding of the process. | Requires collaboration between business analysts and subject matter experts to ensure accurate and detailed models. |

| Use Cases | Suitable for identifying inefficiencies, standardizing tasks, and training employees. | Ideal for simulating scenarios, predicting outcomes, and supporting IT projects and business process optimization. |

There are several types of process maps, each designed to serve a specific purpose. The choice of process map depends on the complexity of the process, the level of detail required, and the intended audience. Here are some common types of process maps:

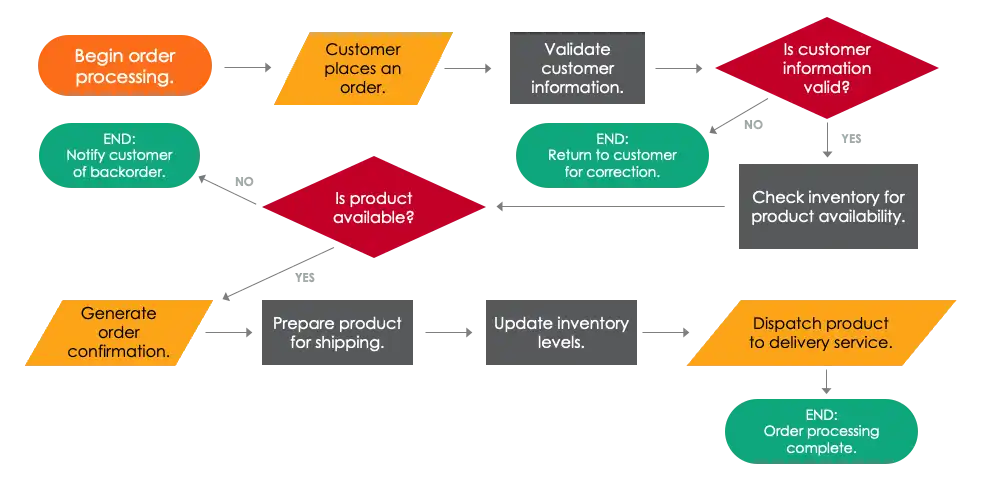

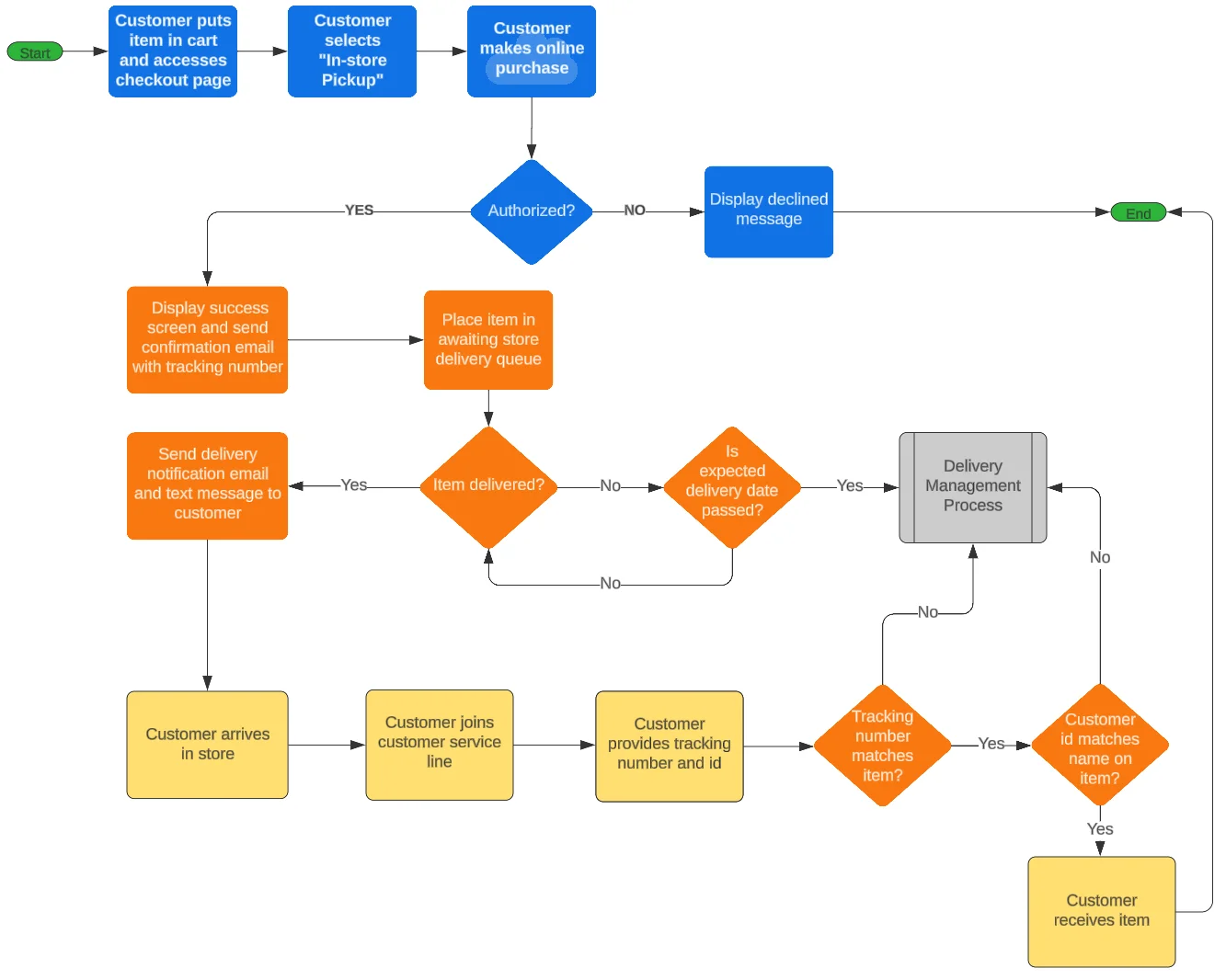

Description: Shows the steps within a process sequentially using mapping symbols to identify inputs, outputs, and decision points.

Use Cases: Continuous improvement, information transfer, integration projects.

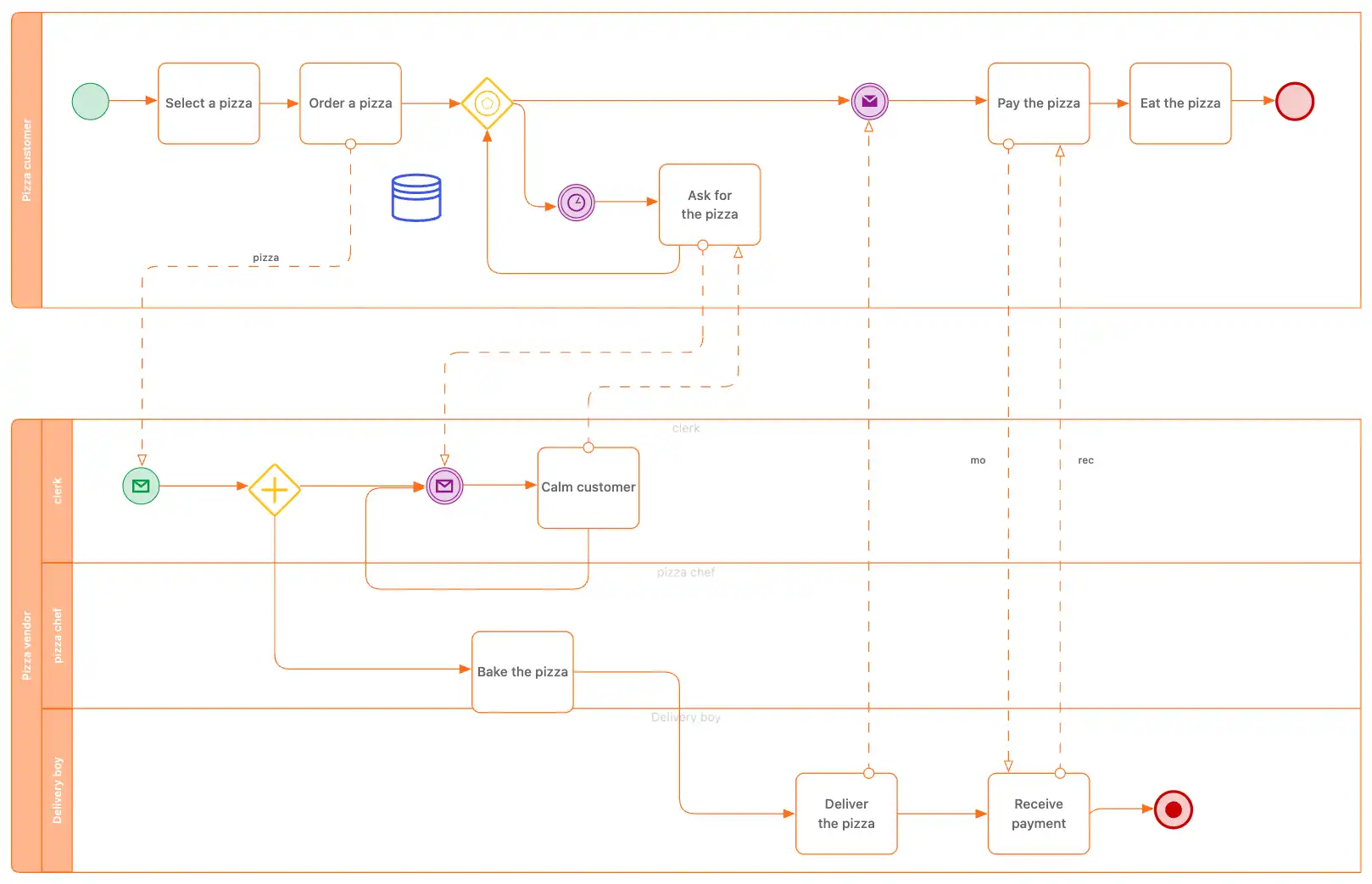

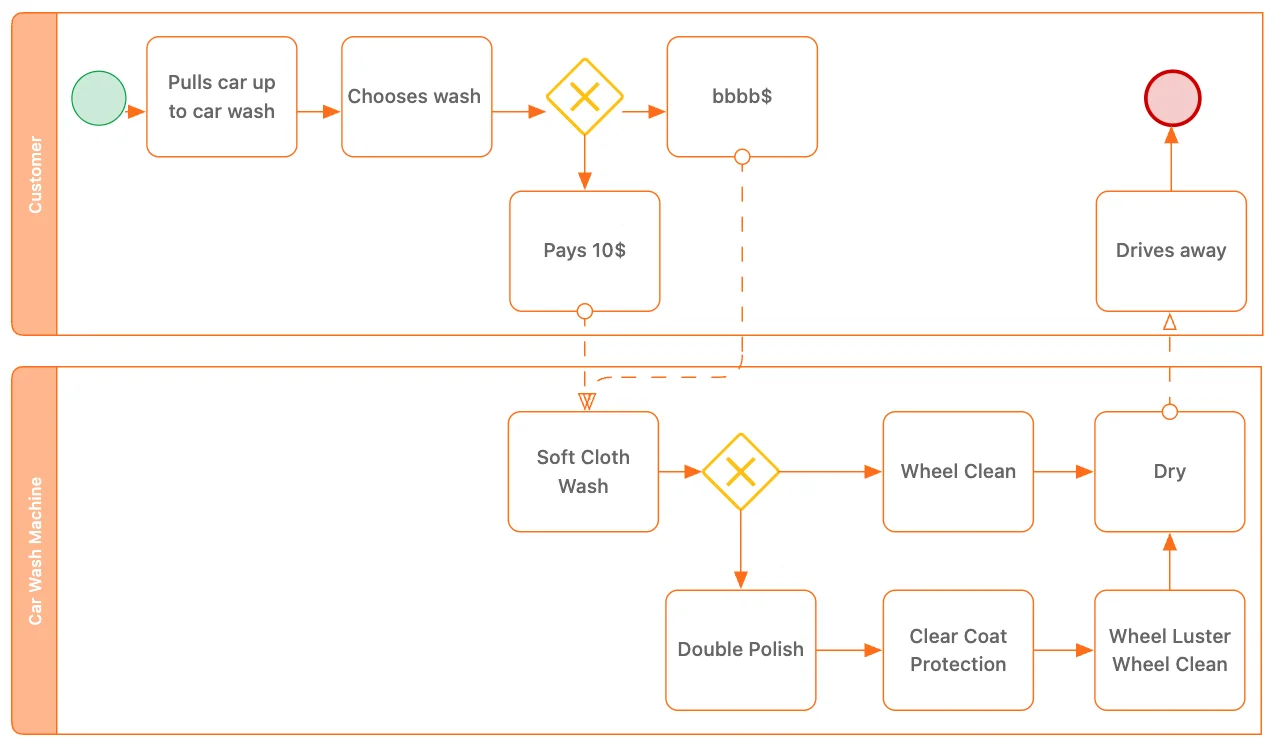

Description: Uses standardized symbols to model business processes in detail.

Use Cases: Business process management, software development, systems engineering.

This is the standard ProcessMind adopted. For more information, see our ultimate guide on BPMN 2.0 .

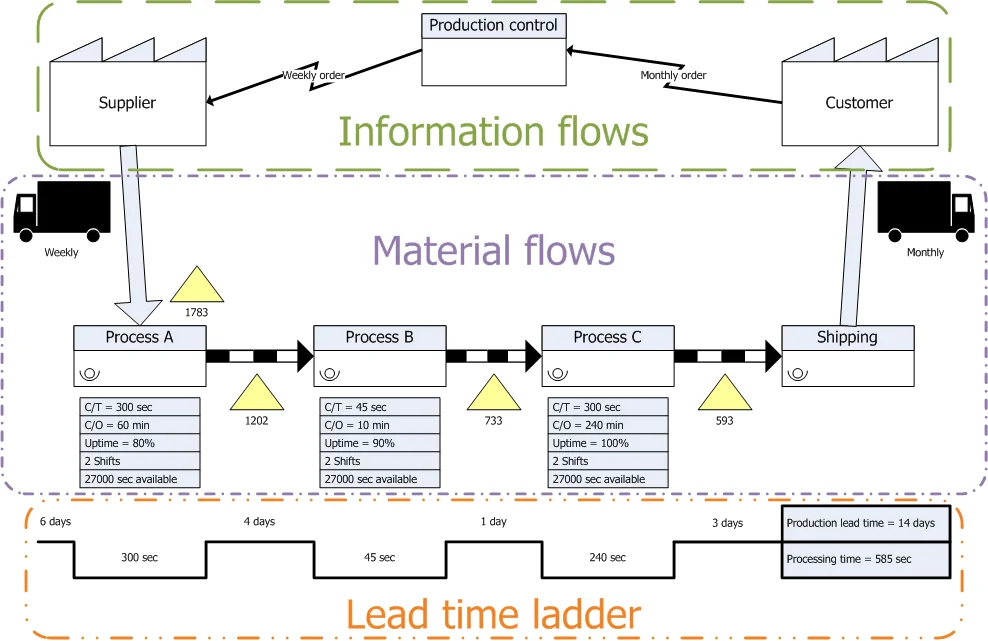

Description: Connects work to the value it delivers to the customer, illustrating steps from raw material or idea to the customer.

Use Cases: Lean practices, manufacturing, continuous improvement.

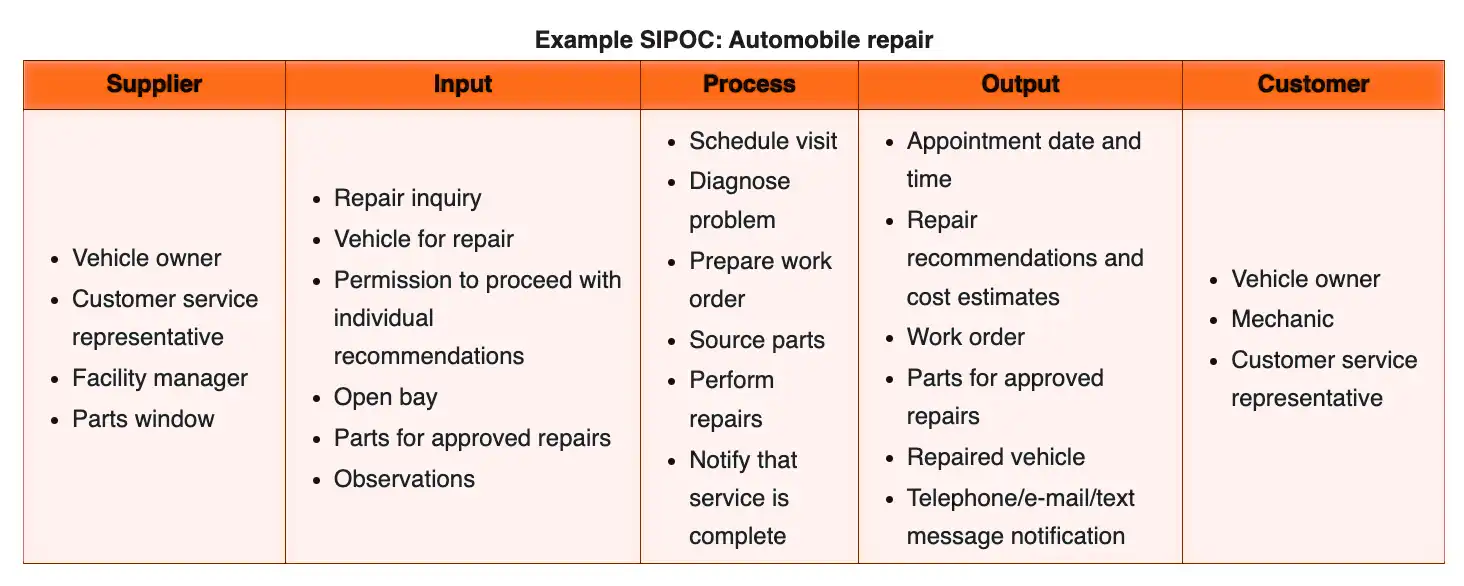

Description: Illustrates suppliers, inputs, process, outputs, and customers for key process elements.

Use Cases: Defining project scope, processes with multiple stakeholders.

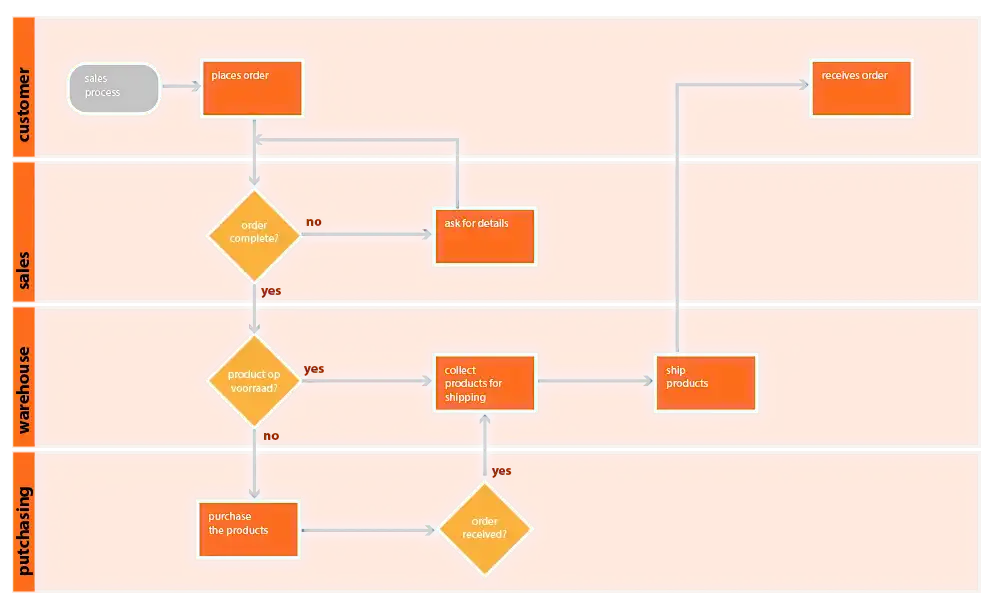

Description: Displays the necessary steps in a process that spans multiple functional areas, with each lane focusing on a specific area.

Use Cases: Sprint planning, cross-functional processes.

Swimlanes are also available in BPMN 2.0 diagrams as Participants and Lanes. See What is BPMN 2.0? for more information.

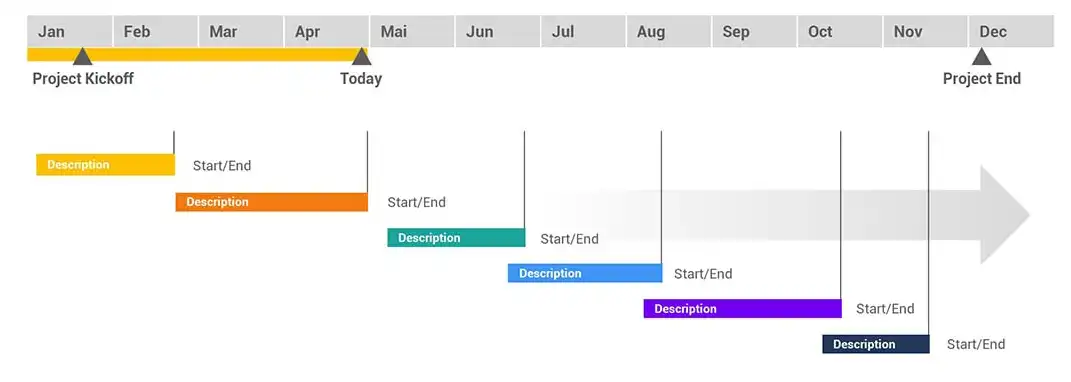

Description: Visualizes project schedules, showing tasks, durations, and dependencies.

Use Cases: Project management, scheduling.

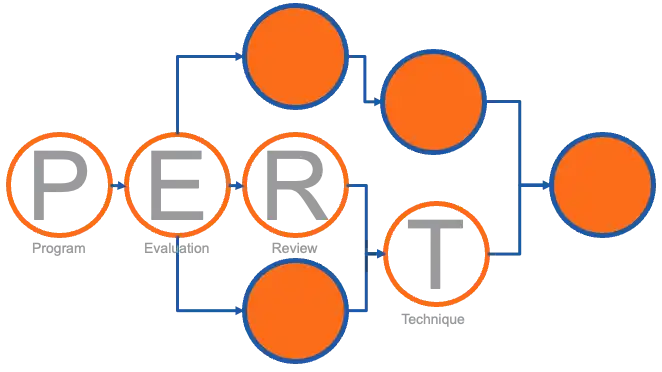

Description: Displays tasks in a project, their durations, and dependencies.

Use Cases: Project planning, time management.

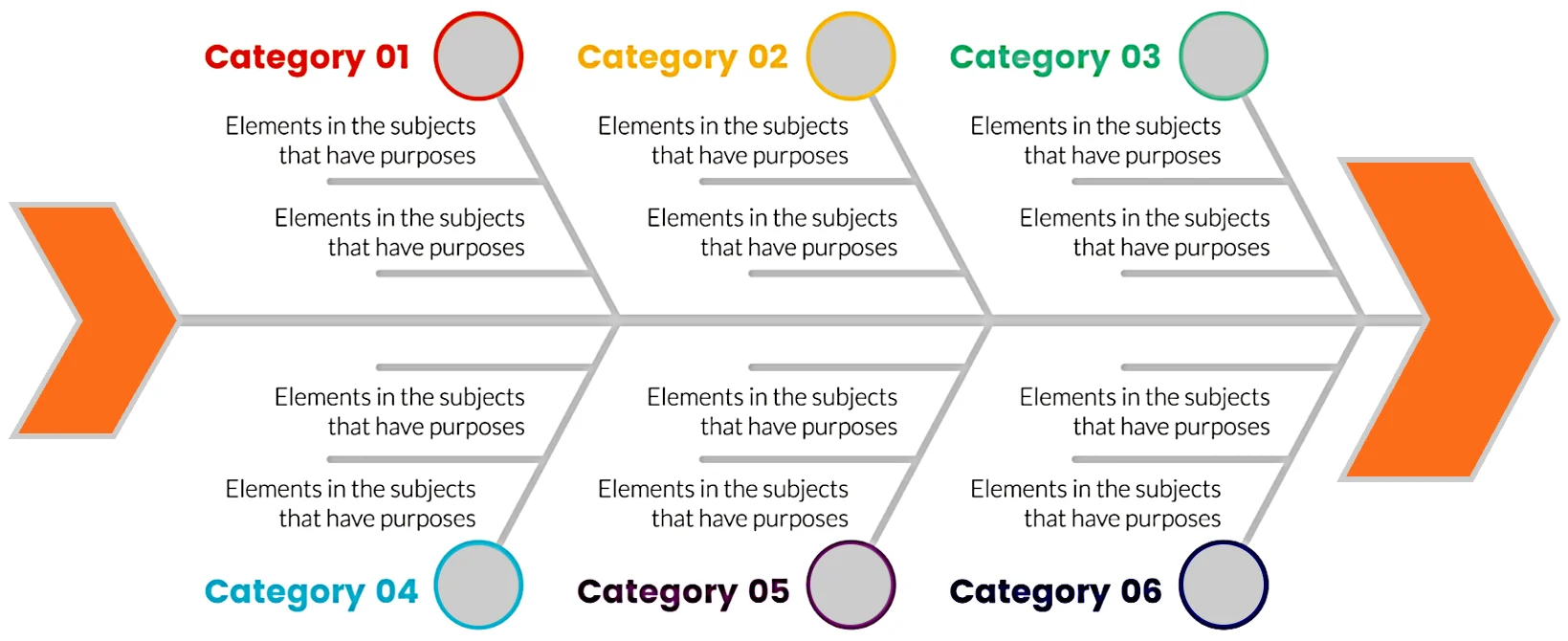

Description: Identifies potential causes of a problem, categorizing them into branches.

Use Cases: Root cause analysis, problem-solving.

Description: Visualizes the flow of tasks and activities in a process.

Use Cases: Workflow optimization, process improvement.

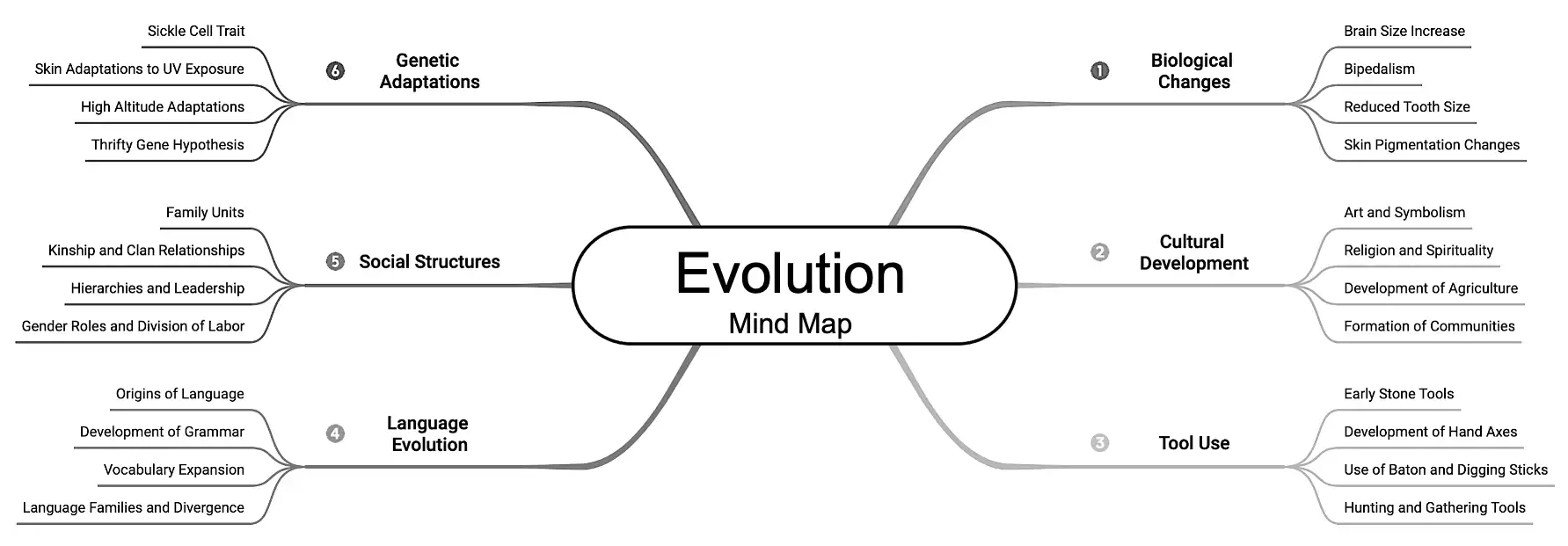

Description: Represents ideas and concepts around a central theme.

Use Cases: Brainstorming, idea generation.

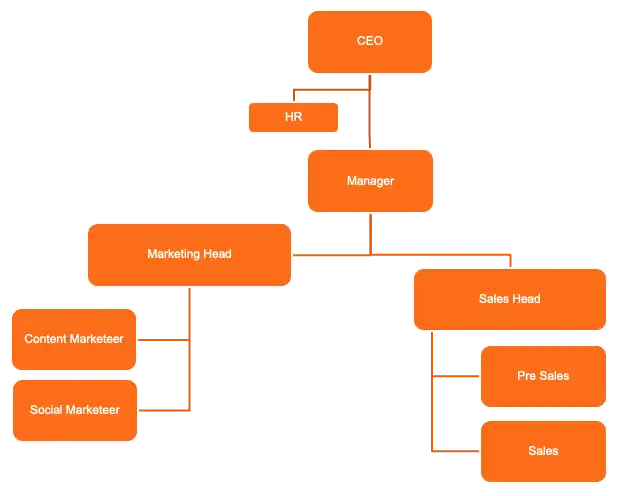

Description: Shows the structure of an organization, including roles and relationships.

Use Cases: Organizational planning, HR management.

Description: Visualizes decision points and possible outcomes.

Use Cases: Decision-making, risk analysis.

Process Modeling is a systematic approach to visualizing a process from start to finish. It involves identifying the steps, inputs, outputs, and decision points in a process and representing them in a clear and concise manner. Here is the ultimate process for creating and using a process map:

This is a comprehensive list, so apply what works best for your specific needs. Be clear about your objectives and open to feedback. Remember, Process Modeling is a continuous improvement tool that can help your business grow and succeed.

Process Modeling is a powerful tool for visualizing and improving business processes. However, there are common mistakes that can hinder the effectiveness of process maps. Here are the top mistakes to avoid in Process Modeling:

Avoid Overcomplicating the Map

Do not include unnecessary details that can make the map confusing and hard to follow.

Do Not Exclude Key Stakeholders

Ensure all relevant team members and stakeholders are involved in the Process Modeling to avoid missing critical information.

Do Not Ignore Feedback

Failing to incorporate feedback from stakeholders can lead to an inaccurate or incomplete process map.

Avoid Using Inconsistent Symbols

Using different symbols for the same elements can create confusion and misinterpretation.

Do Not Skip Validation

Always review and validate the process map with stakeholders to ensure accuracy and completeness before implementation.

Avoid Making Assumptions

Do not assume you know all the steps; gather input from those who perform the tasks.

Do Not Neglect Updates

Failing to update the process map as processes change can render it obsolete.

Avoid Lack of Detail

Do not omit critical steps or decision points, as this can lead to misunderstandings.

Do Not Overlook Training

Ensure that team members are trained on how to read and use the process map effectively.

Avoid Isolated Creation

Do not create the process map in isolation; collaboration is key to capturing the full process accurately.

Now, let’s explore the differences between Process Modeling and Process Mining. Both are crucial for understanding and enhancing business processes, but they have distinct purposes and employ different techniques.

First, let’s define Process Modeling and Process Mining:

Process Modeling is a visual tool that illustrates how work gets done by showing a series of events that produce an end result. It is often used to identify areas for improvement within a business or organization. Process maps help standardize repetitive tasks, visualize workflows, and boost productivity by spotting bottlenecks and inefficiencies. They enable teams to coordinate inputs and decision points, and communicate the steps and dependencies in a process from start to finish. Process Modeling is a practical way to refine any business process and is commonly used in continuous improvement projects.

Process mining is a technique used to analyze and monitor business processes based on event logs. It involves extracting knowledge from event logs readily available in today’s information systems to visualize and analyze the actual processes as they are executed. Process Mining provides insights into the real performance of processes, uncovering deviations from the intended process flow, identifying bottlenecks, and highlighting areas for improvement. It uses data-driven techniques to create a detailed and accurate picture of how processes operate in reality.

| Aspect | Process Modeling | Process Mining |

|---|---|---|

| Purpose | Focuses on visualizing and understanding the current state of a process to identify areas for improvement. | Aims to analyze, improve, and monitor processes based on actual data from event logs. |

| Detail Level | Provides a high-level overview of a process, showing the sequence of steps and interactions. | Offers a detailed and comprehensive representation of a process, including data flows, decision points, and potential outcomes. |

| Tools and Techniques | Utilizes simple visual tools like flowcharts and diagrams. | Employs advanced data analysis techniques and software tools to extract and analyze event log data. |

| Collaboration | Often involves team members and stakeholders to create a shared understanding of the process. | Requires collaboration between data analysts and process owners to ensure accurate and detailed analysis. |

| Use Cases | Suitable for identifying inefficiencies, standardizing tasks, and training employees. | Ideal for monitoring process performance, identifying deviations, and supporting continuous improvement initiatives. |

Process mining can significantly enhance Process Modeling by providing data-driven insights into how processes actually operate. Here are some ways process mining can help Process Modeling:

Validation of Process Maps: Process mining can validate the accuracy of process maps by comparing the mapped processes with the actual processes as recorded in event logs. This ensures that the process maps reflect the true nature of the processes.

Identification of Deviations: Process mining can identify deviations from the intended process flow, highlighting areas where the actual process differs from the mapped process. This helps in pinpointing inefficiencies and areas for improvement.

Discovery of Hidden Processes: Process mining can uncover hidden processes that may not be apparent in traditional process maps. These hidden processes can be critical to understanding the full scope of the process and identifying improvement opportunities.

Performance Analysis: Process mining provides detailed performance metrics, such as cycle times, waiting times, and throughput rates. These metrics can be used to enhance process maps by incorporating performance data, making them more informative and actionable.

Continuous Monitoring: Process mining enables continuous monitoring of processes, providing real-time insights into process performance. This allows organizations to keep their process maps up-to-date and aligned with the actual processes.

Process Modeling can also guide process mining efforts by providing a structured framework for analysis. Here are some ways Process Modeling can guide process mining:

Defining the Scope: Process maps can help define the scope of process mining efforts by identifying the key processes and activities to be analyzed. This ensures that the process mining analysis is focused and relevant.

Identifying Key Metrics: Process maps can help identify the key metrics and performance indicators to be monitored through process mining. This ensures that the analysis is aligned with the organization’s goals and objectives.

Providing Context: Process maps provide context for the data analyzed through process mining. They help in understanding the relationships between different activities and the overall process flow, making the analysis more meaningful.

Facilitating Communication: Process maps can facilitate communication between data analysts and process owners by providing a visual representation of the process. This helps in ensuring that the analysis is aligned with the process owners’ understanding and expectations.

Supporting Improvement Initiatives: Process maps can support improvement initiatives by providing a baseline for comparison. The insights gained from process mining can be used to update and refine process maps, making them more accurate and actionable.

Another benefit is improved communication, as both visual and data-driven insights facilitate better stakeholder alignment. This combination also supports continuous improvement by offering real-time insights into process performance and enabling regular updates to process maps, ensuring processes are optimized and aligned with organizational goals.

Informed decision-making is greatly enhanced, as a comprehensive understanding of processes and their performance ensures decisions are based on accurate and reliable information. In conclusion, Process Modeling and process mining are complementary techniques that, when combined, provide a powerful approach to process analysis and improvement. Together, they enhance efficiency, communication, and alignment with organizational objectives.

To learn more about Process Mining and Process Modeling, visit ProcessMind.

A comprehensive guide to leveraging data for effective process improvement and business transformation.

Compare Disco and ProcessMind to find the best fit for your team's process mining needs in 2025. Discover key features, pricing, and use cases.

Compare Celonis process mining with ProcessMind for 2025. Discover which process mining software fits your business needs, budget, and goals.

Discover how ProcessMind and UiPath compare for process mining, modeling, and simulation. Find the right platform for your business in 2025.

Instant access, no credit card, no waiting. Experience how mapping, mining, and simulation work together for smarter, faster decisions.

Explore every feature, uncover deep insights, and streamline your operations from day one.

Start your free trial now and unlock the full power of Process Intelligence, see real improvements in under 30 days!

We use cookies to enhance your browsing experience, serve personalized content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.